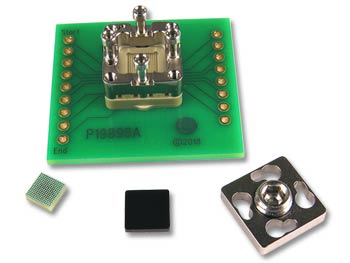

Spring Pin Sockets for 0.3mm Pitch Devices

Ironwood’s Spring Pin sockets are ideal for prototyping and testing almost any BGA or QFN device application with the recent introduction of 0.3mm pitch probes. These sockets provide excellent signal integrity yet remain cost effective. Innovative outer spring with fixed coils SBT contact technology delivers low signal loss (-1dB at 17GHz) and supports BGA or QFN/MLF with pitches down to 0.3mm.

BGA sockets are mechanically mounted over a target system’s BGA lands using mounting and alignment holes at proper locations (page 2 of the individual socket drawing shows recommended PCB layout information). These low-profile sockets are only 2.5 mm per side larger than actual IC packages (industry’s smallest footprint). They support IC devices with body sizes ranging from 50mm down to 1mm.

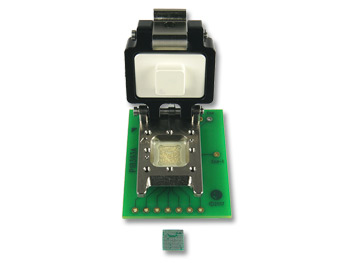

If the backside of the target PCB contains capacitors and resistors, a custom insulation plate with cavities cut for those components can be designed. This insulation plate sandwiches between the backing plate and target PCB. The sockets have a precision design, which guides the IC to the exact position for connection of each ball and uses an aluminum heat sink screw to provide compressive force. The sockets are designed to dissipate up to several watts without extra heat sinking and can handle higher power dissipation with a custom heat sink and axial fan. The user simply places the IC into the socket, then places the compression plate, swivels the lid, and applies torque to the heat sink screw to connect the IC. Alternate lid options are available such as snap lid (shown in figure 2) which has integrated springs inside the lid for proper application of compressive force. If there are pre-existing holes in the PCB, spring pin sockets can be custom designed to accommodate those holes (please call Ironwood Tech Support @1-800-404-0204).

Spring pin sockets use SBT contact technology for high endurance and wide temperature applications. SBT Contact is a machined contact with outside spring that provides a robust solution for Burn-in & Test applications. Solutions are available for 0.3mm to 1.27mm LGA, BGA, QFN, QFP, SOIC and other packages. Contact technology has a 3 part system which includes a top plunger, a bottom plunger, and a spring. The Beryllium Copper plungers are machined and assembled to a stainless steel spring resulting in a precision, low cost contact.

Typical specifications for the 0.3mm pitch contact technology include:

- 17GHz bandwidth @-1dB

- Contact resistance under 100mOhm

- Self inductance 0.55nH

- Capacitance under 0.34pF

- Operating temperature range -55C to +150C

- Insertion/Extraction life over 100,000 cycles

- Current rating at ambient temperature is 2A per pin

For quote, please fill the form with required information or call us at 1-800-404-0204