Sockets for High Speed Applications

For BGA, QFN, or LGA applications, GTP contact technology provides >94 GHz signal speed and can additionally be used in high cycle life applications such as ATE. These sockets support pitches from 0.2 mm to 1.27 mm.

For BGA, QFN, or LGA applications, GTP contact technology provides >94 GHz signal speed and can additionally be used in high cycle life applications such as ATE. These sockets support pitches from 0.2 mm to 1.27 mm.  Ironwood's GT sockets are ideal for prototyping and testing almost any BGA device application. These IC sockets provide excellent signal integrity yet remain cost effective. Innovative elastomer interconnect technology that delivers low signal loss (1dB at 94GHz) and supports BGA packages with pitches down to 0.2mm was utilized in these sockets. GT BGA sockets are mechanically mounted over a target system's BGA lands using mounting and alignment holes at proper locations (page 2 of the individual socket drawing shows recommended PCB layout information). These low-profile sockets are only 2.5 mm per side larger than actual IC packages (industry's smallest footprint).

Ironwood's GT sockets are ideal for prototyping and testing almost any BGA device application. These IC sockets provide excellent signal integrity yet remain cost effective. Innovative elastomer interconnect technology that delivers low signal loss (1dB at 94GHz) and supports BGA packages with pitches down to 0.2mm was utilized in these sockets. GT BGA sockets are mechanically mounted over a target system's BGA lands using mounting and alignment holes at proper locations (page 2 of the individual socket drawing shows recommended PCB layout information). These low-profile sockets are only 2.5 mm per side larger than actual IC packages (industry's smallest footprint).

For BGA, QFN, or LGA applications, GTP contact technology provides >94 GHz signal speed and can additionally be used in high cycle life applications such as ATE. These sockets support pitches from 0.2 mm to 1.27 mm.

Ironwood's GT sockets are ideal for prototyping and testing almost any BGA device application. These IC sockets provide excellent signal integrity yet remain cost effective. Innovative elastomer interconnect technology that delivers low signal loss (1dB at 94GHz) and supports BGA packages with pitches down to 0.2mm was utilized in these sockets. GT BGA sockets are mechanically mounted over a target system's BGA lands using mounting and alignment holes at proper locations (page 2 of the individual socket drawing shows recommended PCB layout information). These low-profile sockets are only 2.5 mm per side larger than actual IC packages (industry's smallest footprint).

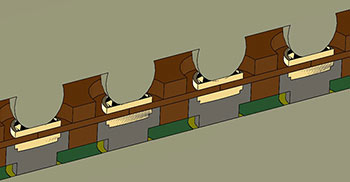

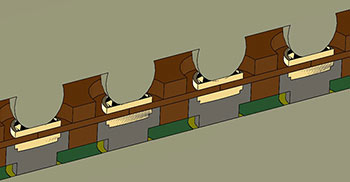

Ironwood’s GTP sockets are ideal for prototyping and production testing almost any BGA, QFN, or LGA device application. These IC sockets provide excellent signal integrity and high mechanical endurance. Innovative elastomer interconnect technology, that delivers low signal loss (1dB at 94GHz) and supports BGA, QFN, and LGA packages with pitches down to 0.2mm. With the addition of proprietary gold crown, our GTP sockets are also able to deliver greater than 200,000 cycles, when properly configured.

Ironwood’s GTP sockets are ideal for prototyping and production testing almost any BGA, QFN, or LGA device application. These IC sockets provide excellent signal integrity and high mechanical endurance. Innovative elastomer interconnect technology, that delivers low signal loss (1dB at 94GHz) and supports BGA, QFN, and LGA packages with pitches down to 0.2mm. With the addition of proprietary gold crown, our GTP sockets are also able to deliver greater than 200,000 cycles, when properly configured.

They support IC devices with body sizes ranging from 70mm down to 1mm. Larger body sizes may require a backing plate. If the backside of the target PCB contains capacitors and resistors, a custom insulation plate with cavities cut for those components can be designed. This insulation plate sandwiches between the backing plate and target PCB. The sockets have a precision design, which guides the IC to the exact position for connection of each ball and uses an aluminum heat sink screw to provide compressive force. The sockets are designed to dissipate up to several watts without extra heat sinking and can handle up to 600 watts with a custom heat sink. The user simply places the IC into the socket, places the compression plate, swivels the lid, and applies torque to heat sink screw to connect the IC. If there are pre-existing holes in the PCB, a GT elastomer BGA socket can be custom designed to accommodate those holes (please call Ironwood Tech Support @1-800-404-0204). Typical GT elastomer BGA socket with lever actuated lid is shown in the figure.

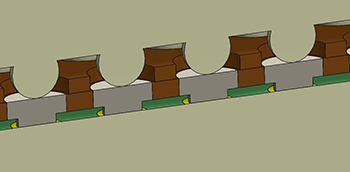

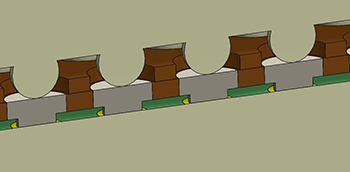

GT is a new elastomer technology that has silver particles held in a conductive column like buttons which are embedded in a non-conductive polymer substrate on a proper pitch that provides high compliance and extreme temperature ranges. GT is available for BGA, PoP and other packages from 0.2mm to 1.27mm pitch. The contact resistance is <30 milliohms. The operating temperature range for the elastomer is -55C to +160C.

GTP utilizes the same great elastomer technology of GT, while adding a proprietary gold crown to deliver industry leading signal performance and high endurance.

If there is no room to put mounting holes for socket on a customer’s board, the socket can be used with alternate SMT options or with Thru hole options. Custom sockets to accommodate rectangular body shapes, odd sizes, and devices with pitches down to 0.2mm can be developed in short lead time. BGA package specifications can vary widely between manufacturers. We have found that it is most effective for us to ask customers for information about the specific device to be socketed and then provide a quote. You can fill the form with required information or call us at 1-800-404-0204.