Board-to-Board Connectors for High Speed Applications

Connectors using elastomer, spring pin, and pin/socket interconnect technologies provide up to 94 GHz of bandwidth in the smallest possible footprint, for both prototype and production applications. These rugged interconnects utilize our laser-and-laminate processes for rapid development and short lead-times, without expensive hard tooling. They support pitches from 0.3mm to 2.54mm and heights from 0.25mm to 5mm.

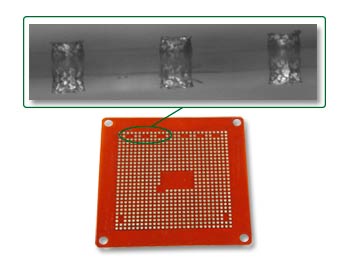

Connectors using conductive elastomeric contacts provide the highest possible bandwidth. Elastomer technology utilizes conductive silver particles held in silicon column-like buttons, which are embedded in a non-conductive polymer substrate on a proper pitch, that provide compliance on both sides. Board-to-board or flex-to-board can be accomplished in custom laser cut footprints from 0.2mm to 1.27mm pitch. Elastomer buttons can also be deployed in coaxial configurations for impedance matching. Contact resistance is <30 milliohms, with an operating temperature range of -55C to +160C.

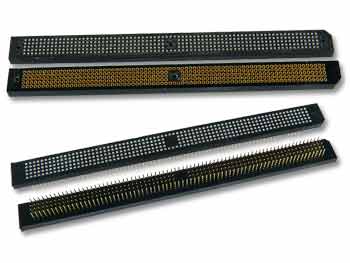

Connectors using spring pin contacts offer flexible height options. Inherently rugged, spring pins provide high endurance and are utilized in wide temperature applications. Spring pins are constructed of either stamped contacts with external springs, or precision screw machined components. The housings are laser cut and laminated, allowing for easy customization of contact location and mounting options, without the need for hard tooling. Solutions are available for 0.3mm to 1.27mm pitch with height ranging from 1mm to 5mm. The contact resistance is <30 milliohms, with a current carrying capacity up to 8A, across an operating temperature range -55C to +180C.

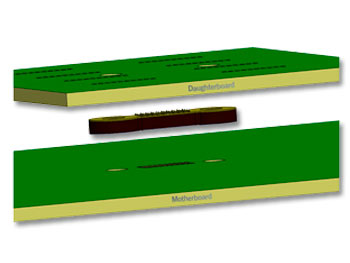

Connectors using pin-clip male/female contacts provide mate/unmate options between mother and daughter board. These high-performance connectors consist of two halves, a female socket array and male pin array. The female socket array consists of machined pins mechanically encapsulated into an assembly that matches the male pin array of similar construction. The female array is soldered to the mother board using standard RoHS soldering methods, while the male array is soldered to the daughter board. To mate the arrays, they are simply plugged together. Available in both lead and lead free solder ball types, the arrays feature gold plated mating surfaces for reliable connection, requiring half the force of conventional connectors. The electrical path of the BTB connector from the top connection point on the male pin module to the solder ball on the female socket is 4.5 mm. These connectors passa environmental tests (MIL-STD) and are qualified for a various range of applications including automotive, military, communication, industrial, etc. Male/female board-to-board connectors are available in many different pin counts with 1mm & 0.8mm pitch, with customs delivered in days without hard tooling.