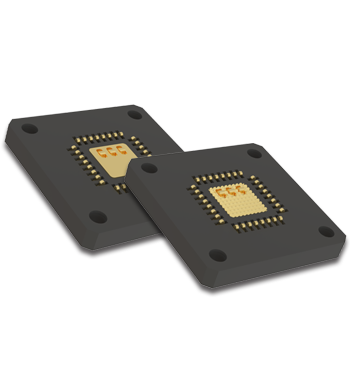

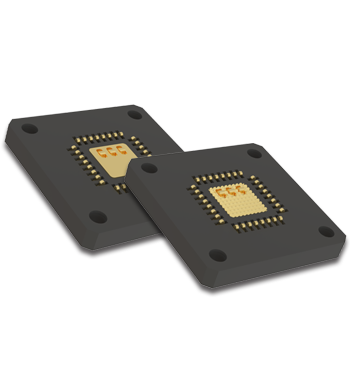

ATE Cartridge with PicoRaptor

Ironwood Electronics introducing its first, of many, production Test Contactors into the Automated Test Environment, also known as ATE. The cartridge is the first for the ATE environment, the technology uses Ironwood’s proprietary lamination process that provides simplicity to help increase Mean Time Between Assist (MTBA).

The PicoRaptor contact is a rigid pin that uses a single elastomer for ease of rebuild that is a high-performance contact for high frequency and high insertion count. It’s available in 1mm and 2mm length with pitch down to 0.30mm pitch. The single P elastomer provides firm contact to the load board and to the tip of the contact while providing a contact wipe that keeps Cres stable by keeping solder migration to a minimum off the contact tips with a proprietary Advance Contact finish (ACF) and prolongs load board life.

Ironwood’s Cartridge was designed for efficiency, while reducing your cost of test. Leave the contactor on the loadboard, remove the alignment plate (ALPL) and the cartridge, insert a new cartridge with the existing ALPL and resume testing.

| Mechanical Specifications | PicoRaptor-1 | PicoRaptor-2 |

| Contact Pin Uncompressed Height(mm) | 0.95 | 1.6 |

| Contact Compliance(mm) | 0.2 | 0.2 |

| Contact Tip Coplanarity(mm) | ±0.05* | ±0.05 |

| Gram Force per Contact(g) | 30±10 | *20 ~ 40g |

| Wipe Length(mm) | 0.09 ~ 0.12 | *0.1 |

| Number of Insertion – Laminated Housing | ≥6M | ≥6M |

| Number of Insertion – Pin (Matte Tin.) Number of Insertion – Pin (NiPd) |

200K ~ 300K* | 300K ~ 500K* |

| Number of Insertion – Elastomer | ~200K | *300K ~ 400K |

| Operating Temperature | -45 ~ 155°C | -45 ~ 155°C |

| Socket Frame | Torlon 5030 or Equivalent |

Torlon 5030 or Equivalent |

| Contact Cartridge | Cirlex® Polyimide | Cirlex® Polyimide |

| Pin Material | BeCu – NiAu | BeCu – NiAu |