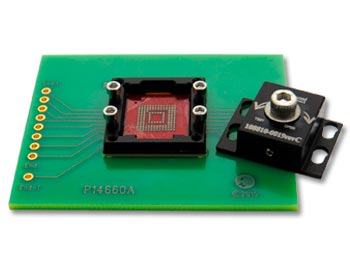

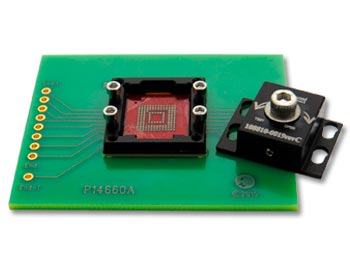

SMT Elastomer Sockets

Ironwood Electronics NZGT socket is a device size or near device size footprint test socket incorporating high performance GT elastomer. Ironwood can design a socket to work with any type IC packages- BGA, LGA, QFN, DFN and even leaded devices where you need to fit a socket in place of your device to allow fast, easy testing and development.

Features and Benefits

Near Zero PCB footprint

The socket footprint is only 1 mm larger (0.5 mm per side) than the device for Near Zero Configurations. Typically this footprint will fit into any end application allowing the Elastomer socket to be directly reflowed into the same location as the device. Depending on the ball configuration (BGA only) some designs can be made to a true Zero Foot Print.

High Performance Elastomer

GT is a proven technology used in other Ironwood’s test sockets. It has silver particles held in a conductive column like buttons which are embedded in a non-conductive polymer substrate on a proper pitch that provides high compliance and extreme temperature ranges. GT is available for various packages from 0.35mm to 1.27mm pitch. The contact resistance is <30 milliohms. The operating temperature range for the elastomer is -55C to +160C. GT elastomer will be placed inside the socket after reflow using SMT process.

Lid Options

The Bolt Down Lid (standard) is a simple way to push the device into the socket. Optional Sliding Lid or ½ turn Lid is also available for higher insertion applications.

Excellent Signal Performance

Depending on the electrical performance needed, innovative SMT elastomer interconnect technology that delivers low signal loss (1dB at 43GHz).

Request For Quote or call us at 1-800-404-0204.